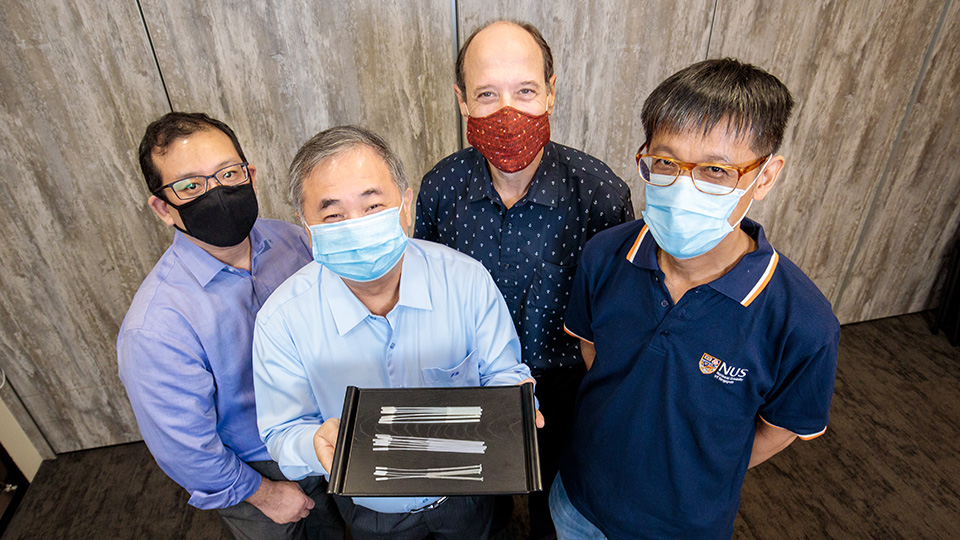

Researchers from National University of Singapore (NUS) have developed three swab designs to address the global shortage of nasopharyngeal (NP) swabs, and to ensure Singapore has a sustainable supply of these products.

Developed in less than two months, the Python swab demonstrated comparable accuracy and performance, with no significant difference against the standard swab, NUS said in a press statement.

As such, the 3D-printed Python swab was deemed safe and acceptable for patient use, and could help mitigate strained resources in the escalating COVID-19 pandemic.

A patent for the Python swab has been filed, and two local companies – Structo Pte Ltd and Eye-2-Eye Communications Pte Ltd – are mass-producing the swabs.

Since the outbreak of COVID-19, there has been a global surge in demand for NP swabs, a key element in testing for SARS-CoV-2. Commercially available NP swabs used in COVID-19 test kits are often out of stock due to supply chain disruptions.

“We are pleased to contribute our expertise to address the pressing need for nasopharyngeal swabs. As part of NUS’ contribution towards the nation’s fight against COVID-19, the design of the Python swab is free for use in Singapore," said Associate Professor Yen Ching-Chiuan, Co-Director of the Keio-NUS CUTE Center and one of the lead researchers of the project.

Additionally, to further increase the production of suitable swabs for Singapore and the region, another NUS team led by Professor Freddy Boey, NUS Deputy President (Innovation & Enterprise), introduced two new designs, named ‘IM2’ and ‘IM3’, that could be manufactured using injection moulding.

“Injection moulding as a manufacturing process is inherently faster than 3D printing as multiple units of the swabs can be produced in a given cycle. Several hundred swabs can be produced in a few minutes using the moulding process,” explained Prof Boey.